Landscaping Equipment Maintenance Checklist Template (+Free PDF Download)

Landscaping and lawn care businesses need well-maintained equipment to deliver high-quality services efficiently.

Regular equipment inspections reduce downtime and costly repairs, but keeping track of maintenance schedules for a fleet of mowers, trimmers, and edgers is challenging.

Checklists are a first step, but equipment maintenance software will take you further

Landscape maintenance checklists help ensure you check equipment regularly so it functions properly, which avoids breakdowns. This landscape checklist template lets you stay on track with preventive maintenance through daily, monthly, and annual tasks.

Learn about landscape equipment maintenance best practices and the limitations of using analog methods to track upkeep for your company’s assets.

The article also explains how landscaping business technology streamlines maintenance tasks and helps your crews work more efficiently across your organization.

Benefits of using an equipment maintenance checklist

Landscape equipment maintenance checklists ensure every member of your team follows a regular maintenance schedule to maximize equipment longevity. It also ensures crews follow standard operating procedures (SOP) before and after using equipment.

A structured equipment maintenance checklist provides the following landscaping business benefits:

Reduces repairs: Routine maintenance keeps equipment working efficiently, decreases the need for parts replacement, and minimizes breakages.

Avoids downtime: When lawn equipment breaks down, it disrupts work, sometimes grounding a crew for an entire day. A maintenance checklist ensures your crews check key components and identify potential problems before they become emergencies.

Provides procedures: A checklist sets consistent workflows for inspecting, using, and cleaning lawn maintenance equipment, especially when you work with subcontractors or seasonal hires.

Increases productivity: Well-maintained equipment works how it should, so your crews work faster and consistently deliver high-quality landscaping services.

Remember that a landscaping equipment maintenance schedule depends on the type of equipment and how often it’s used. The following sections are examples of typical daily, monthly, and annual maintenance tasks.

Daily maintenance tasks

Daily tasks keep equipment running in good condition. When you have routes packed with commercial properties, your team needs equipment that’s ready to service tens of thousands of square feet, whether they’re mowing, edging, or applying herbicide.

→ If crews discover broken equipment once they’re on the job site, it can damage customer relationships and destroy your day’s profit margins.

Train your crews to perform these checks before leaving headquarters so they can adjust or replace equipment if necessary.

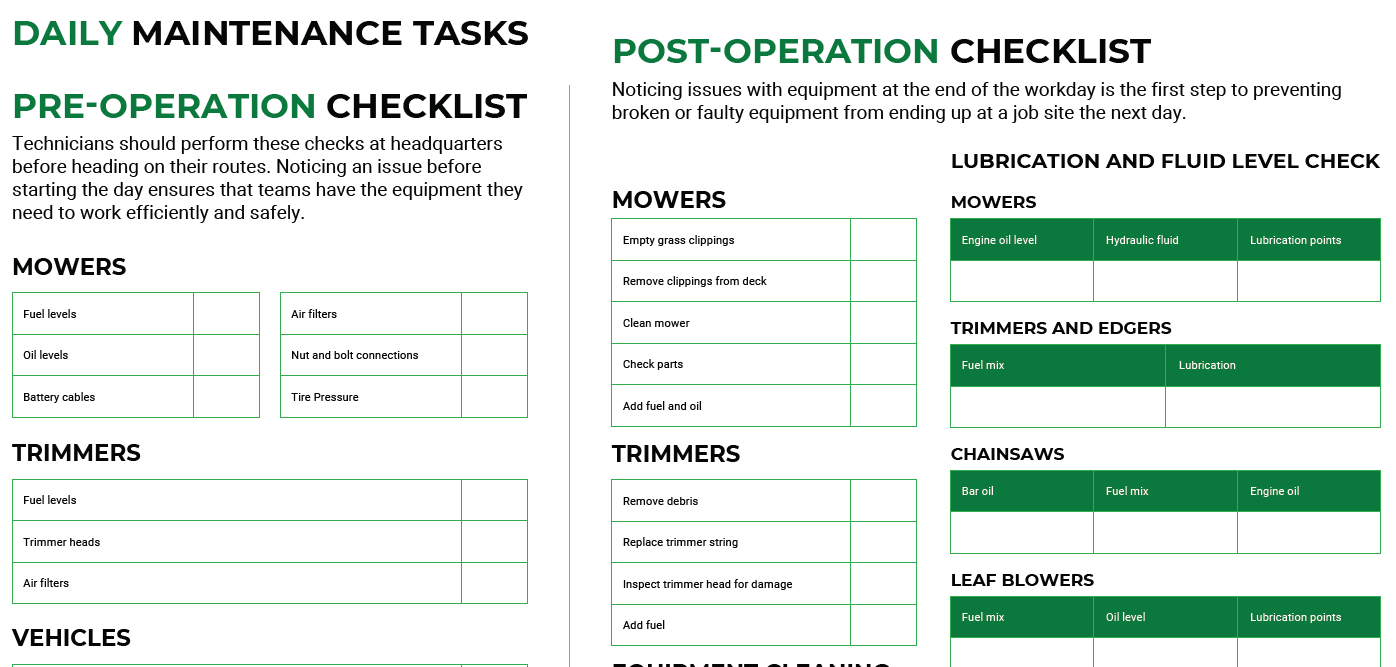

Pre-operation inspection

Inspecting equipment before use keeps crews safe and ensures your equipment works optimally. Before using any landscaping equipment, check to ensure it’s free of debris and has no loose parts.

Basic pre-operation inspection includes checking:

Mowers

Fuel levels

Oil levels

Battery cables

Air filters

Nut and bolt connections

Tire pressure

Trimmers

Fuel levels

Trimmer heads

Air filters

Vehicles

Oil levels

Transmission fluid

Lights

Tires

Trailers

Hitch and connections

Power cable

Tire pressure

Racks or storage for small equipment and hand tools

Post-operation check

Post-operation checklists ensure crews clean equipment, refill fluids, and inspect for damaged, loose, or missing parts.

Mowers

Empty grass clippings

Remove grass clippings from the mower deck

Clean mower

Check parts

Add fuel and oil if needed

Trimmers

Remove debris

Replace trimmer string

Inspect the trimmer head for damage

Add fuel if needed

Equipment cleaning and washing

Clean equipment looks good, works better, and lasts longer. During the 100 Days of Hell, cleaning mowers and edgers might feel futile, but dirt, grass clippings, and other debris trap moisture and cause corrosion or rust.

During high-usage seasons, debris and build-up also inhibit peak performance.

Clean the following equipment:

Mowers and mower decks

Mower attachments, such as aerators and dethatchers

Trimmers

Edgers

Chainsaws

Wood chippers and mulching equipment

Pruners and shears

Rakes and shovels

By spending a few minutes cleaning equipment at the end of the shift, crews can stay ahead of more significant issues later and ensure their gear is ready for the demands of the next day.

As part of the daily maintenance, landscaper crews should also keep their vehicles and trailers clean and free of debris.

Lubrication and fluid level check

Fluids keep equipment motors and parts running smoothly and extend equipment lifespan. Teams should check fuel and oil levels daily.

Without proper fluid levels, equipment won’t function properly. Operating equipment with less-than-optimum fluid levels could lead to long-term damage or inoperable equipment.

Weekly to monthly maintenance tasks

Weekly to monthly maintenance tasks address the parts of equipment that aren’t addressed by daily clean-up tasks.

These more in-depth tasks include things like checking filters, belts, and spark plugs to reduce excess wear and keep equipment running efficiently.

Oil changes and filter replacements

Regular oil changes and filter replacements top the list of essential maintenance tasks.

Follow manufacturer instructions on how often to change oil in mowers and other equipment. The cadence of oil changes will vary depending on the motor and the type of oil it requires. Typically, landscapers change their mower oil and the oil filter after 50-100 hours of run time.

As a rule of thumb, apply grease to a mower’s moving parts every time you change the oil and filters. Regular grease application also benefits other equipment, such as gas leaf blowers.

Blade sharpening and replacements

Professional-looking turf relies on sharp lawn mower blades. Dull blades tear, rather than cut, grass which can lead to long-term damage on client properties.

On average, landscapers should sharpen or replace mower blades at least every 20 hours, although many landscapers prefer to sharpen blades daily or every other day. Balanced blades ensure an even cut so grass can efficiently absorb water and nutrients.

Also, sharpen cutting equipment such as chainsaws, pruners, and shears regularly.

Belt and chain inspection

Inspecting belts and chains for wear avoids breakdowns at the job site.

Look for and replace mower deck belts that look:

Loose

Burnished

Cracked

Any signs of wear

If they’re not replaced, equipment mows unevenly, and the belts eventually break. For equipment with chains, such as drive chains, check wearing and tension to ensure the equipment runs as it should.

Spark plug checks and replacement

Spark plugs are essential for lawn mower engines to start and run efficiently.

The manufacturer or equipment manual can provide insight into how often you should change spark plugs. Typically, landscapers change spark plugs once a year or whenever they change mower oil and filter.

Spark plugs in handheld equipment, such as trimmers and leaf blowers, should also be regularly checked and replaced.

Regular upkeep for spark plugs ensures your team won’t be in the middle of a hectic route dealing with equipment that won’t start.

Dirty spark plugs can also hurt your bottom line in less dramatic ways, such as causing poor acceleration and decreased fuel efficiency.

Tire pressure and tread inspection

Inspect mower tire pressure and tread to ensure the best stability and performance.

Consult manuals for correct tire pressure, which will extend the life of your tires. Low tire pressure can affect steering, traction, lawn mower deck pitch, and cut height. Too much pressure or uneven pressure can lead to an uneven cut.

Inspect tire treads to ensure the proper traction when mowing and turning.

Battery maintenance

Check and charge equipment batteries regularly. While the time varies depending on the battery and equipment, landscapers may get two to five years out of lawn mower batteries.

Signs of a bad battery include the lawn mower failing to start or a clicking sound when attempting to start the mower.

Charge the batteries during cold weather to extend the life of lawn mower batteries in the off-season. Some landscapers remove the mower batteries, store them in a warmer place, and charge once or twice before the season begins.

Regularly check and charge batteries on other equipment, such as battery-powered handhelds or power tools.

Annual maintenance tasks

Annual equipment and vehicle inspections enable landscapers to maintain equipment, proactively manage problems, and boost business operations.

Full equipment inspection

Give all equipment a thorough once-over to ensure parts function properly. Inspecting equipment before it needs repair helps landscapers extend their equipment's life and plan ahead for replacements. Use a landscaping equipment inspection checklist so nothing gets overlooked.

Professional servicing and overhauls

Lawn mowers and heavy equipment benefit from professional service and repair. While landscapers need to consider the price, mower and machinery experts know how to maintain and fix equipment. Research top-rated maintenance-service providers in your area to find the best fit for your business.

Inventory and replacement planning

Plan for future repairs by building an inventory of spare parts and equipment. Keeping extra parts and sharpened blades on hand quickly returns equipment to service. Track assets and implement a budget to replace aging equipment and grow your fleet.

Landscaping equipment maintenance: Best practices

It’s vital to perform regular inspections for landscaping equipment, but it's difficult for busy landscapers to track all the details.

Routine inspections often catch service needs before they become problematic while avoiding downtime caused by faulty gear.

Follow these green industry equipment maintenance best practices to improve inspections and maintenance:

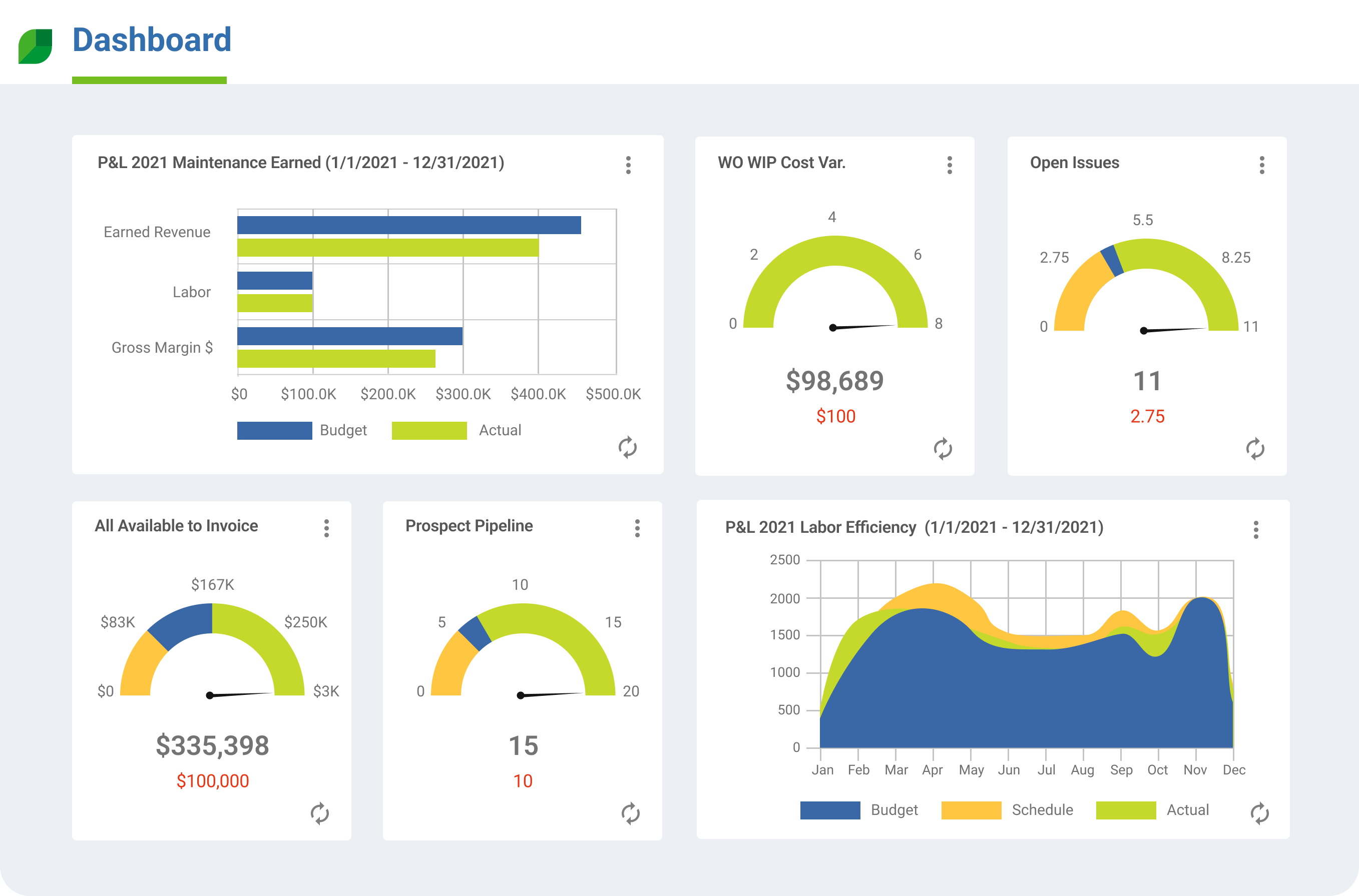

Implement landscape business software: Use software to streamline inspection tasks and connect inspections with your operations. Aspire landscape business software empowers landscapers to proactively manage equipment and vehicle maintenance with asset inventory management, trigger maintenance alerts, and customizable inspection checklists.

Track equipment service hours: Automate your maintenance schedule by tracking landscaping equipment service hours and vehicle mileage. Aspire’s landscape equipment management features enable landscapers to easily schedule maintenance regularly to improve equipment service life and avoid downtime.

Perform mobile inspections: Use a mobile app to improve communication and increase inspection visibility. Aspire’s mobile inspection capabilities allow crews in the field to submit inspection results, work orders, and service history. Managers can see at a glance whether equipment passed inspection and what issues must be addressed.

Implement the proper equipment maintenance process to keep your equipment and crews efficient and productive.

Start proactively managing your equipment

Landscape equipment maintenance checklists help your business capture inspection details, but paper templates fall short.

Aspire landscape business software gives you full visibility into operations so you can work more efficiently and profitably. Aspire’s equipment tracking functionality provides unparalleled visibility into asset inventories, allowing you to track equipment and vehicles by manufacturer, size, model, class, or route.

Automate maintenance alerts and track service details on every piece of equipment. Monitor equipment use to identify usage trends, make better decisions, and forecast accurately. Increased visibility helps you better manage your business and plan for growth.

Ready to streamline your landscaping business operations? Request a demo to see Aspire features in action.